bioMérieux’s Innovation - Why is Augmented Diagnostics the current best protection for manufacturers against food and health scandals?

May 5th, 2023

3 questions to Guillaume Dancoisne, Business Development Manager Europe at bioMérieux

420,000 deaths per year, 600 million sick people (Figure from the World Health Organization)… not to mention factory closures and employees who find themselves unemployed.

The global reality, found in the balance sheets of planetary organisations or revealed by the media, reminds the world of the agri-food industry of the damage that food contamination can cause.

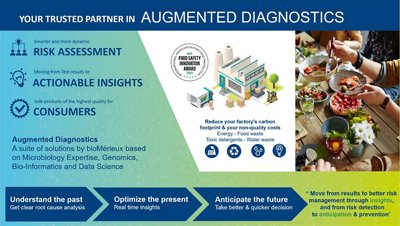

All players want to protect themselves against this but the real question is: How to be most effective? bioMérieux, who is recognised for its global expertise in food safety and quality, highlights, after a confidential phase, its innovative ecosystem: Augmented Diagnostics (formerly Predictive Diagnostics, name during the project phase), which was rewarded by the Food Safety Innovation Award 2022

Augmented Diagnostics - formerly Predictive Diagnostics - was highlighted by the Food Safety Innovation Award 2022. What justified this award?

The jury was not wrong. It really is a new approach, which shakes up the way of thinking of the world of the agri-food industry in the face of food safety. Augmented Diagnostics, its official name, combines the very latest state-of-the-art techniques at the crossroads of microbiology, data science, bioinformatics and genomics (study of the genome), associated with the support of our research teams of world-renowned experts.

This approach makes it possible to internally gain, within the company, efficiency and speed in decision-making, thus making it possible to reduce losses and expenses whilst also gaining brand protection. Simultaneously, at the consumer level it allows trust building by choosing, for example, to communicate on this method in complete transparency. Today, even more than yesterday, consumers are expecting quality and healthy products, having become expert consumers, it is no longer enough to say that the products are good, you also have to prove it to them.

This communication is not yet obvious, the subject is complicated because we all know that health crises are the bane of industrialists and talking about food safety is sometimes very complicated. Regardless, the existence of bacteria such as E.coli, Salmonella, Listeria, Cronobacter, as seen in the recent crises, is a reality that cannot be denied. They were there before humans and know how to perfectly adapt and even resist conventional biocides (disinfectants).

So it's up to us to be one step ahead and Augmented Diagnostics is the solution, putting you not just one but several steps ahead.

“5 minutes to decide wether or not to stop a production line”

How does this method allow better and quicker decisions to be made in order to avoid complications?

Destruction of batches, prolonged line stoppage, inadequate investments, impact on brand image, reduction in water and chemical product consumption - this is often the reality of manufacturers. Our R&D teams had this in mind when they challenged themselves to help manufacturers speed up their decision-making to avoid these issues. It was their mission!

At bioMérieux, we assume that a manufacturer has 5 minutes to decide whether or not to stop a production line. 5 minutes is very short and it is our frame of reference.

At the level of the tools offered, at the forefront and of optimized use, the R&D teams which have transformed themselves in depth by integrating this new know-how (data science, bioinformatics, genomics) have therefore worked to quickly give visibility and understanding of current and past events that could disrupt production, which are key to help make the right decisions. The Augmented Diagnostics suite of solutions has been modeled around speed.

It is then difficult to communicate figures proving the time and financial savings of this method. Although dozens of companies have already tested this innovative approach, the figures are still confidential. It is not yet the culture of the agro-industrial world to reveal its “secrets”, even if some like the Isigny Sainte-Mère cooperative are a pioneer. (read article)

Another advantage of our approach is our human, expert responsiveness.

At our level, too, we strive to be present during these crises, because these are “tipping points” for an industrialist, who will do everything so that this moment does not happen again. One thing is certain: to make their decision and the following ones, they do not need a plethora of data but to have the right ones and the ability to analyse them and decipher them at a glance. This kind of expertise cannot be invented and we are here for that - efficient and as fast as possible. In Europe, for example, our team responds to them as soon as they receive their message and our technical experts get up to speed, backing up the site personnel who are already numerous in their various controls (raw materials, production environment, finished products ) in order to recover the samples as quickly as possible.

You started three years ago in a confidential way. Dozens of companies have since tested Augmented Diagnostics. What is their feedback?

Above all, a relief after having experienced it. An acceleration in the understanding of a problem, a better visibility of events and therefore time saving for the "right" decision. The entry ticket for Augmented Diagnostics, 30,000 euros, is not in question. The approach allows them to bring back intelligence and reasoning where in previous crises, it was vagueness and incomprehension.

One of the companies avoided a loss of 2 million euros due to avoiding having to halt a production line.

Before Augmented Diagnostics, this would have stopped them dead, whereas with the solution, they could see that the problem did not come from there.

It was the complete mapping of their factory, combined with other optimised parameters, and artificial intelligence, which helped them to have this more wholistic vision. This then allowed the manufacturer to adapt its response to the presence of microorganisms on its site.

Furthermore, it is a timely solution for manufacturers, when saving water and energy have become high priorities. It is therefore necessary, for example, to be efficient in the use of cleaning products (biocides). Washing down a production line with conventional products, sometimes without knowing where the problem lies, while several days later recognizing that everything has to be redone because the bacteria is resistant, is simply not allowed anymore!

To make the right decisions and adopt the best practices, you still need to bring in expertise and be aware of the problem you are facing.

Curious to find more?