Ready to Eat Food Microbial Detection and Quality Control

January 05, 2022

?qlt=85&ts=1675158189108&dpr=off)

READY-TO-EAT MEALS: FOOD SAFETY CONCERNS AND QUALITY CONTROL

Ready-to-eat (RTE) meal manufacturers have a lot on their plates, especially when it comes to spoilage and contamination. The presence of pathogens in ready-to-eat foods is a more serious threat to public health than their presence in raw meat products because ready-to-eat foods do not usually receive additional treatments to eliminate these bacteria ; meanwhile, they may contain native microflora including pathogenic bacteria of the raw material from which they are prepared.

The most common bacteria in ready-to-eat foods are Salmonella, Listeria monocytogenes, Escherichia coli, Campylobacter jejuni, Staphylococcus aureus, Bacillus cereus, and Clostridium perfringens. Since ready-to-eat foods are consumed without any additional treatment, the risk of foodborne outbreaks is high if they are improperly prepared or stored.

In order to deliver high-quality and safe food, ready-meal producers must maintain strict protocols for quality control and bacteria detection.

THE RISE OF CONTAMINATION IN READY-TO-EAT FOODS

Ready-to-eat foods are usually consumed immediately at the place of sale, without any preparation or treatment. They include raw, partially cooked, hot, cold and frozen foods. The Codex Alimentarius Commission (CAC) defines ready-to-eat foods, as raw foods, or any foods manipulated, processed, mixed, cooked, or otherwise prepared and consumed without additional process. The convenience and flexibility of ready-to-eat meals have increased demand globally. The global market for ready meals is projected to grow at a CAGR (compound annual growth rate) of 4.62% between 2021 and 2026. The demand for these convenience products is on the rise, particularly after the COVID-19 pandemic1.

That’s good news for sales. However, the soar in demand adds stress to the manufacturing line and increases the risk for bacterial spoilage. Recalls and outbreaks are already causing havoc in the ready-meal industry. Ready-to-eat foods are mass-produced from many different ingredients. Processing of poultry, beef, pork, dairy, and produce all pose microbiological risks of their own, but combined, the risk is even higher. With so many components coming together, the manufacturing process is complex, prone to errors, and exposed to risks of microbiological contamination. Ready-to-eat foods are by far the number one category of recalled food products. With microbiological contamination being the leading reason for U.S. food recalls2, ready meal producers must conduct consistent and accurate quality control processes.

HOW TO ENSURE QUALITY CONTROL IN READY MEALS?

Contamination prevention is imperative to food safety. Prevention starts with plant layout and design to avoid cross-contamination between raw materials and finished product. Spoilage prevention requires consistent cleaning, sanitizing and testing throughout critical care points along with the manufacturing line.

Minimizing cross-contamination risk includes the five stages of food production management: product and process development, Good Manufacturing Practices (GMPs), Hazard Analysis & Critical Control Points (HACCP), Sanitation Standard Operating Procedures (SSOPs), and distribution and preservation control of the cold chain3.

STANDARDS AND REGULATIONS IN THE READY MEALS INDUSTRY

Federal, regional, and Local government agencies regulate and control food safety protocols in both the European Union and the United States. The Food Safety System (FSS) in the European Union manages food safety guidelines for 28 member countries. In the United States, the Food and Drug Administration (FDA) of the United States Department of Health and Human Services (HHS) and the Food Safety Inspection Service (FSIS) of the United States Department of Agriculture (USDA) lead the federal oversight to protect consumers.

At a local level, food processors use Hazard Analysis Critical Control Points (HACCP) to manage their food safety systems. HACCP is an internationally recognized method of identifying and managing food safety-related risks. A well-structured quality plan identifies these critical care points (CCPs) or quality defects, establishes their limitations, monitors them, and corrects planning to maintain a consistent quality throughout the manufacturing chain4.

COMMON SPOILERS AND BACTERIA IN READY-TO-EAT FOODS

Listeria monocytogenes is one of the most important foodborne pathogens and the most deadly one, causing a higher number of deaths than any other foodborne pathogen. Because the vast majority of foods recalled for Listeria are refrigerated RTE foods, Listeria monocytogenes is the number one pathogen of concern for ready-to-eat foods manufacturers today5.

In addition to Listeria, bacteria such as Salmonella, Escherichia coli, Clostridium botulinum and Clostridium perfringens also survive and grow under the acid conditions in ready-to-eat foods.

Cold-chain adherence and best-sanitation practices aid in bacteria prevention. Preservatives also help increase ready-to-eat food safety and shelf-life, however consumer demand for fewer preservatives limits processors’ use of them.

With increasing consumer demand for ready-to-eat meals and reduction of preservatives, along with complex supply chains using multiple ingredients, what is the best way to reduce spoilage and maintain your brand integrity?

HOW TO DETECT CONTAMINATION THROUGHOUT THE READY MEALS MANUFACTURING PROCESS?

Environmental testing is the number one control for Listeria in ready-to-eat food factories. Developing and implementing an environmental monitoring program (EMP) is unique to every operation. Testing and monitoring regularly by swabbing areas most likely to harbor Listeria and other pathogens helps actively find positives. Environmental monitoring data helps identify areas of microbial activity that might require longer-term fixes, like replacing uncleanable equipment, repairing infrastructure, and altering the workflow of human and mobile equipment5.

Choosing the right testing technology is specific to every ready meal production. Traditional microbiology testing costs the least, however it can take days to get results. Rapid microbial testing produce results within hours, instead of days.

Invented in 1983, polymerase chain reaction (PCR) is now widely used to rapidly make millions to billions of copies of a specific DNA sample, allowing lab techs and scientists to take a very small sample of DNA and amplify it to a large enough amount to study in detail. In the case of food production, the PCR method quickly detects contamination unseen by the human eye.

OUR UNIQUE DIAGNOSTIC SOLUTIONS TO PREVENT CONTAMINATION IN READY MEALS

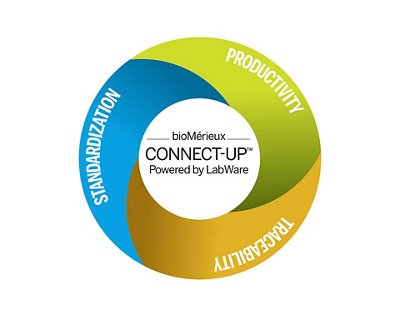

Detection is a priority, yes. What about prevention of contamination risks? How can ready meal processors own a detection process that is easy, rapid and accurate AND prevent quality issues by becoming more proactive? With our unique Predictive Diagnostics offer combining automated diagnostic solutions and custom data-analysis tools and services, bioMérieux helps ready meals processors be predictive over reactionary in their daily quality management system.

PROTECT YOUR BRAND WHILST IMPROVING OPERATIONAL EFFICIENCY

FULLY AUTOMATED SOLUTIONS ADAPTED TO YOUR SPECIFIC NEEDS OF THROUGHPUT, TIME TO RESULT, AND MICROBIAL TESTING

With results in as little as 24 hours, bioMérieux automated solutions for pathogen detection (VIDAS®, GENE-UP®) and quality indicators enumeration (TEMPO®) deliver rapid, accurate, and traceable results to enable faster decisions and corrective actions throughout the process, so ready-to-eat food processors can release products sooner. Our solutions provide valuable insights they need to stay in compliance and protect their brand integrity.

Simple

• User-friendly interface for efficient and effective testing

• Standardized and simplified workflow

• LIMS-compatible for easy data tracking and compliance

Rapid

• Provides results within 1 day

• Increase productivity

Reliable

• Globally validated by certification bodies according to AOAC-OMA and ISO16140-2 standards

Flexible

• Flexible throughput to match any lab’s needs

• Manage peaks of activity

• Comprehensive testing menu for pathogen and quality indicators available

Prevent quality issues by becoming proactive

Using sequencing and data predictive models, we map pathogens in any ready-to-eat food factory and identify root causes of contamination. This valuable information will help manufacturers optimize their environmental monitoring program and ultimately prevent potential scraps.

We can also help identify and efficiently manage raw material and supplier risks and orient the auditing effort and the support focus.

In addition, Predictive Diagnostics, helps to identify and efficiently manage your supplier risks.

ON THE SAME SUBJECT

REFERENCES

1 Mordor Intelligence. Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026). Ready Meals Market. 2021

2 Statistics and facts on food recalls. Statista Research Department. 2020

3,5 5 Steps to the Safety & Quality of Refrigerated RTE Foods. Food Safety Magazine.2001

4 Aadil RM, Madni GM, Roobab U, Rahman U, Zeng XA. Quality Control in the Beverage Industry. Science of Beverages. 2021;17:1-38. doi: 10.1016/C2017-0-02391-1

6 Gombas, D. McEntire, J. Guidance On Environmental Monitoring And Control Of Listeria For The Fresh Produce Industry. United Fresh Food Safety & Technology Council. 2018

?qlt=85&ts=1711733667895&dpr=off)